The system manages inventory, tracks production orders, and oversees the raw material requirements, allowing manufacturing units to streamline their operations. It also generates production schedules and tracks inventory movements across different stages of the manufacturing process.

Key Features:

- Inventory Management (Raw materials, Work-in-progress, and Finished Goods)

- Production Order Management

- Purchase Order Management for raw materials

- Bill of Materials (BOM) Management

- Production Schedule Tracking

- Reporting & Analytics Dashboard

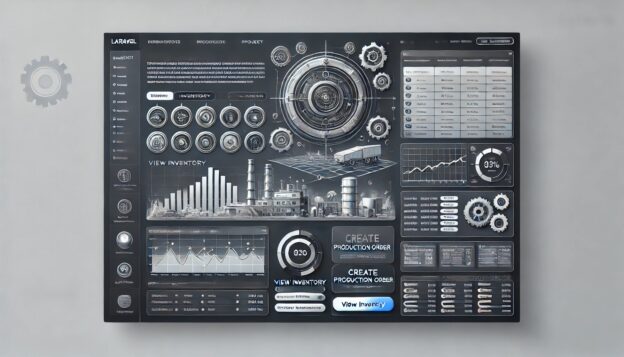

Wireframes:

Here’s a rough outline of the wireframes required for this project.

1. Dashboard

- Overview: Summary of stock levels, pending production orders, and recent activity.

- Charts: Material in stock, orders in progress, and finished goods in warehouse.

2. Inventory Management

- List of items (raw materials, WIP, finished goods)

- Buttons: Add new item, view stock levels, update stock, reorder items.

- Search and filter by item category, status (WIP/Finished), or reorder status.

3. Production Order Management

- List of current production orders with status (Pending, In Progress, Completed)

- Buttons: Create new production order, update order status, cancel order.

- Columns: Order ID, Date, Product, Quantity, Deadline, Status.

4. Purchase Orders

- List of Purchase Orders (Pending, Approved, Delivered)

- Create new purchase order for raw materials.

- View supplier info, expected delivery dates, etc.

5. Bill of Materials (BOM)

- Page for defining the Bill of Materials for each finished product.

- Fields for raw materials required, quantities, lead times, etc.

6. Reports

- Generate reports for stock levels, order history, and material consumption over time.

- Filters by date range, product, or supplier.

User Stories:

1. User Registration & Login:

- As a manufacturing manager,

- I want to register and log in to the system,

- so that I can manage manufacturing operations securely.

- Acceptance Criteria:

- Users can register with email, password, and role.

- Users receive a confirmation email upon registration.

- Users can log in with correct credentials, or see error messages if incorrect.

- Acceptance Criteria:

2. Manage Inventory:

- As a storekeeper,

- I want to manage the inventory of raw materials, work-in-progress items, and finished goods,

- so that I can keep track of stock levels and reorder materials when required.

- Acceptance Criteria:

- Users can view a list of inventory items with search and filter options.

- Users can add or update stock levels for raw materials, WIP, or finished goods.

- Users receive notifications when stock levels are below the reorder threshold.

- Acceptance Criteria:

3. Create and Track Production Orders:

- As a production manager,

- I want to create and update production orders,

- so that I can track the progress of orders and ensure timely delivery.

- Acceptance Criteria:

- Users can create production orders by selecting product, quantity, and deadline.

- Users can update the order status as ‘In Progress’ or ‘Completed’.

- The system sends notifications if an order is approaching its deadline.

- Acceptance Criteria:

4. Generate Purchase Orders for Raw Materials:

- As a procurement officer,

- I want to create purchase orders for raw materials,

- so that I can ensure raw materials are available for production on time.

- Acceptance Criteria:

- Users can select raw materials, supplier, and quantity to create a purchase order.

- Users can approve or cancel purchase orders.

- Users receive a notification when the purchase order is fulfilled by the supplier.

- Acceptance Criteria:

5. Bill of Materials (BOM):

- As a product engineer,

- I want to define and manage the Bill of Materials for each product,

- so that I can ensure the correct raw materials are used for manufacturing.

- Acceptance Criteria:

- Users can define the raw materials and quantities required for each finished product.

- Users can update the BOM if product specifications change.

- BOM details are linked to production orders to ensure correct materials are used.

- Acceptance Criteria:

6. View Production Reports:

- As a operations manager,

- I want to generate production and inventory reports,

- so that I can analyze trends and make data-driven decisions.

- Acceptance Criteria:

- Users can generate reports for specific time periods.

- Reports include stock levels, material consumption, and production order history.

- Users can download reports in PDF or CSV format.

- Acceptance Criteria:

Acceptance Criteria:

1. User Management:

- User registration and login functionality should work correctly.

- Admin can create and manage user roles (e.g., production manager, storekeeper, procurement officer).

2. Inventory Management:

- The system should maintain an accurate list of raw materials, WIP, and finished goods.

- Users can adjust stock levels and the system should automatically calculate reorder points.

3. Production Order:

- Users can create, update, and delete production orders.

- The system should track order status and send reminders for upcoming deadlines.

4. Purchase Orders:

- The system should allow the creation of purchase orders for raw materials.

- Purchase orders can be approved or canceled, and notifications sent upon delivery.

5. Bill of Materials:

- BOM functionality should allow users to define raw materials for each finished product.

- BOM details should be integrated with production orders for accuracy.

6. Reporting & Analytics:

- Reports should display inventory and production metrics, with filters for date and product.

- Users can download reports in PDF or CSV format.

detailed breakdown for each section of the Manufacturing Inventory and Order Management System project using PHP Laravel:

1. User Registration & Login

Wireframe Details:

- Login Page:

- Form fields: Email, Password.

- Buttons: Login, Forgot Password.

- Error messages for invalid credentials or account not confirmed.

- Registration Page:

- Form fields: Name, Email, Password, Confirm Password, Role (Storekeeper, Production Manager, Procurement Officer, Admin).

- Button: Register.

- A confirmation email is sent after registration.

- Admin Dashboard – User Management:

- List of all users, with options to create new users, deactivate, or change roles.

User Stories:

- As a user, I want to log in securely, so that I can access the system based on my role.

- As an admin, I want to create and manage users, so that I can assign roles and control access.

Acceptance Criteria:

- Users can register with valid email and password.

- Confirmation emails are sent after registration.

- Admins can view and manage all users.

- System roles control access to different areas of the application.

2. Inventory Management

Wireframe Details:

- Inventory Dashboard:

- Summary of all stock levels (Raw Materials, WIP, Finished Goods).

- Search bar to filter by product category or item.

- Option to reorder materials.

- Stock List Page:

- Columns: Item Name, Category (Raw Material/WIP/Finished Goods), Stock Level, Reorder Threshold, Status (In Stock/Low Stock).

- Buttons: Add New Item, Edit Item, Reorder Item.

- Add/Edit Item Page:

- Form fields: Item Name, Category, Unit (Kg, Pieces, etc.), Current Stock Level, Reorder Point, Supplier.

- Buttons: Save, Cancel.

User Stories:

- As a storekeeper, I want to track raw materials and finished goods, so that I know stock levels at all times.

- As a production manager, I want to see work-in-progress (WIP) stock, so that I can manage production efficiently.

Acceptance Criteria:

- Users can add, edit, and delete inventory items.

- Users can view stock levels in real time.

- The system automatically flags items that are below the reorder point.

- A reorder form can be generated from this module when stock is low.

3. Production Order Management

Wireframe Details:

- Production Order List Page:

- Columns: Order ID, Product, Quantity, Start Date, Deadline, Status (Pending, In Progress, Completed).

- Buttons: Create New Production Order, Edit Order, Cancel Order, Mark as Complete.

- Create New Production Order:

- Form fields: Product, Quantity, Deadline, Notes.

- Buttons: Save, Cancel.

- Production Order Details Page:

- Displays: Product Details, Assigned Team, Progress Tracking, Material Used (from BOM).

- Status updates and notifications for approaching deadlines.

User Stories:

- As a production manager, I want to create and update production orders, so that I can track production progress.

- As a storekeeper, I want to allocate raw materials for a specific production order, so that the production team can begin work.

Acceptance Criteria:

- Production orders can be created with product, quantity, and deadline details.

- Users can update order status (Pending, In Progress, Completed).

- The system sends reminders for orders approaching their deadline.

- Users can track materials consumed during production, tied to the Bill of Materials.

4. Purchase Order Management

Wireframe Details:

- Purchase Order List Page:

- Columns: PO ID, Supplier, Date Created, Items, Status (Pending, Approved, Delivered).

- Buttons: Create New Purchase Order, Edit PO, Cancel PO.

- Create New Purchase Order:

- Form fields: Supplier, Item(s), Quantity, Expected Delivery Date.

- Buttons: Save, Cancel.

- Purchase Order Details Page:

- Displays: Supplier Details, Item List, Expected Delivery, Delivery Status.

User Stories:

- As a procurement officer, I want to create and track purchase orders for raw materials, so that I can ensure raw material availability for production.

- As a storekeeper, I want to receive and approve delivered goods, so that I can update inventory levels.

Acceptance Criteria:

- Users can create, edit, and approve/cancel purchase orders.

- Users receive notifications when items are delivered.

- Purchase orders update the inventory once the materials are received.

5. Bill of Materials (BOM)

Wireframe Details:

- BOM List Page:

- Columns: Product Name, Material, Quantity Required, Lead Time.

- Buttons: Create BOM, Edit BOM.

- Create/Edit BOM Page:

- Form fields: Product, Material, Quantity, Lead Time.

- Buttons: Save, Cancel.

User Stories:

- As a product engineer, I want to create and update the Bill of Materials for finished products, so that production orders are accurate and efficient.

- As a production manager, I want to link BOMs to production orders, so that I can ensure the correct materials are used in production.

Acceptance Criteria:

- Users can define and edit the Bill of Materials (BOM) for each product.

- BOM information is automatically used when creating production orders.

- Users can update the BOM if there are changes to product specifications.

6. Reports and Analytics Dashboard

Wireframe Details:

- Reports Dashboard:

- Summary view: Stock Levels, Production Orders, Raw Material Usage.

- Graphs/Charts for stock trends, material consumption, order progress.

- Filters: Date Range, Product, Supplier.

- Inventory Report:

- Columns: Item Name, Category, Stock Level, Reorder Point, Total Stock Used (during a time period).

- Production Report:

- Columns: Order ID, Product, Quantity Produced, Material Used, Status.

User Stories:

- As an operations manager, I want to generate and download reports, so that I can analyze production efficiency and inventory levels.

- As a procurement officer, I want to view material consumption over time, so that I can better plan future purchases.

Acceptance Criteria:

- Users can generate reports for inventory levels, production orders, and material usage.

- Reports can be filtered by product, supplier, and date range.

- Users can download reports in PDF or CSV format for further analysis.

Technology Stack and Timeline:

- Backend: PHP Laravel

- Models: Inventory, Production Orders, Purchase Orders, BOM, Reports

- Controllers: User, Inventory, Production, Purchase, BOM

- Database: MySQL

- Frontend: Laravel Blade Templating, Bootstrap for UI

- Modules Breakdown:

- Week 1–2: User Authentication, Role Management, and Dashboard setup.

- Week 2–3: Inventory Management, BOM, and Stock Tracking.

- Week 3–4: Production Order Management, Purchase Order Management.

- Week 5: Reporting and Analytics.

- Week 6: Testing and Deployment.

Use a wireframe tool like Figma or Balsamiq to visualize them. Here’s the breakdown:

1. Dashboard:

- Header: “Manufacturing Dashboard”

- Charts: (Left) Inventory Status (bar or pie chart of raw materials, WIP, finished goods), (Right) Production Orders Overview (number of orders in progress, completed, pending).

- Summary Section:

- Total Raw Materials

- Orders Due Today

- Total Finished Goods

- Links: Quick links to “View All Inventory,” “Create New Order,” “Reports.”

2. Inventory Management:

- Header: “Inventory Management”

- Table Layout:

- Columns: Item Name, Category (Raw Material, WIP, Finished Goods), Current Stock, Reorder Point, Status (In Stock, Low Stock).

- Buttons/Actions: Add New Item, Update Stock, Reorder.

- Search & Filter Bar: Search by item name/category, filter by status (low stock).

- Pagination at the bottom for long lists.

3. Production Order Management:

- Header: “Production Orders”

- Table Layout:

- Columns: Order ID, Product Name, Quantity, Deadline, Status (Pending, In Progress, Completed).

- Buttons/Actions: Create New Order, Update Status, Cancel Order.

- Order Details Page:

- Fields for product, quantity, deadline, status updates.

- Progress bar showing percentage of order completion.

4. Purchase Orders:

- Header: “Purchase Orders”

- Form Layout:

- Fields: Supplier Name, Material Name, Quantity, Expected Delivery Date.

- Buttons: Save, Cancel.

- Table Layout for Existing Orders:

- Columns: PO ID, Supplier Name, Status (Pending, Approved, Delivered).

- Buttons/Actions: View, Approve, Cancel.

5. Bill of Materials (BOM):

- Header: “Bill of Materials”

- Table Layout:

- Columns: Finished Product, Required Material, Quantity Needed, Lead Time.

- Buttons/Actions: Edit BOM, Add New BOM.

6. Reports and Analytics Dashboard:

- Header: “Reports & Analytics”

- Filter Bar: Date Range, Product, Supplier.

- Charts:

- (Left) Inventory Usage Over Time (line chart)

- (Right) Production Order Status (bar chart)

- Download Button: Option to download report as PDF or CSV.